"Executive Summary Internet of Things (IoT) in Manufacturing Market: Share, Size & Strategic Insights

CAGR Value

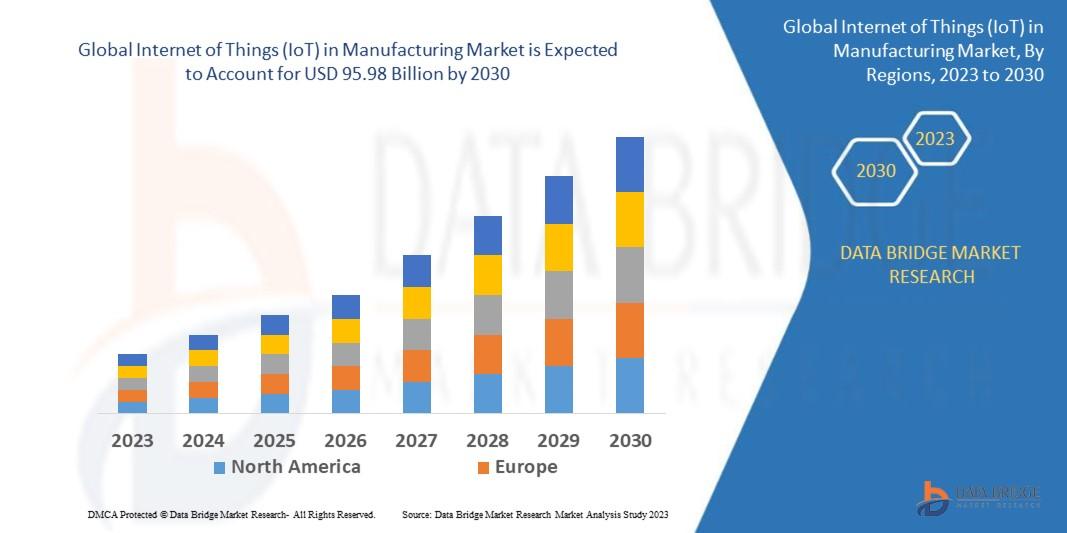

Data Bridge Market Research analyses that the internet of things (IoT) in manufacturing market, valued at USD 24.65 billion in 2022, will reach USD 95.98 billion by 2030, growing at a CAGR of 18.52% during the forecast period of 2023 to 2030.

Internet of Things (IoT) in Manufacturing Market report is structured with the best and advanced tools of collecting, recording, estimating and analysing market data. The insights made available in this market report are based upon SWOT analysis on which businesses can rely confidently. The report provides steadfast knowledge and information of transforming market landscape, what already exists in the market, future trends or what the market expects, the competitive environment, and strategies to plan to surpass the competitors. Internet of Things (IoT) in Manufacturing Market report helps characterize commerce strategies to the businesses of small, medium as well as large size.

Several company profiles included in the reliable Internet of Things (IoT) in Manufacturing Market report can be pretty useful for making any decision associated with revenue, import, export and consumption. The market report guides to get idea about the types of consumers, their reaction and views about particular products, and their thoughts for the improvement of a product. The most suitable method for the distribution of certain products can also be analysed with this market research study. When a business struggles to gain competitive advantage in this swiftly transforming marketplace, then plumping for such Internet of Things (IoT) in Manufacturing Market research report is greatly recommended as it offers a lot of benefits for a thriving business.

Equip yourself with actionable insights and trends from our complete Internet of Things (IoT) in Manufacturing Market analysis. Download now:

https://www.databridgemarketresearch.com/reports/global-iot-in-manufacturing-market

Internet of Things (IoT) in Manufacturing Industry Statistics Overview

Segments

- Application: The IoT in manufacturing market is segmented based on application into predictive maintenance, business process optimization, asset tracking & management, logistics & supply chain management, real-time workforce tracking & management, and others. The increasing focus on predictive maintenance to minimize downtime and optimize operational efficiency is driving the growth of this segment.

- Component: The market is segmented by component into software, services, and hardware. The software segment is expected to witness significant growth due to the rising demand for IoT platforms and analytics tools to extract valuable insights from manufacturing data.

- Vertical: Based on vertical, the IoT in manufacturing market is categorized into automotive, energy & utilities, food & beverages, pharmaceuticals, aerospace & defense, and others. The automotive sector is experiencing rapid adoption of IoT technologies to enhance production processes and improve product quality.

Market Players

- Siemens AG: Siemens offers a comprehensive range of IoT solutions for manufacturing, including industrial automation, cloud platforms, and data analytics, catering to the evolving needs of the industry.

- IBM Corporation: IBM provides IoT solutions tailored for the manufacturing sector, leveraging technologies like artificial intelligence and blockchain to optimize supply chain processes and improve operational efficiency.

- Cisco Systems, Inc.: Cisco offers IoT networking solutions for the manufacturing industry to enable seamless connectivity, real-time monitoring, and enhanced cybersecurity to protect critical operational data.

- General Electric Company: GE provides industrial IoT solutions for manufacturing, focusing on smart machines, predictive maintenance, and data analytics to drive productivity and innovation in production operations.

The global IoT in manufacturing market is witnessing significant growth driven by the increasing adoption of connected devices, automation technology, and data analytics in the manufacturing sector. The demand for real-time monitoring, predictive maintenance, and process optimization is spurring the deployment of IoT solutions to enhance operational efficiency, reduce downtime, and improve overall productivity. With the emergence of advanced technologies like artificial intelligence, machine learning, and blockchain, market players are offering innovative IoT solutions tailored to the unique requirements of manufacturing companies. The integration of IoT technology across various verticals such as automotive, energy, and pharmaceuticals is reshaping the manufacturing landscape and paving the way for smart, connected factories of the future.

The Internet of Things (IoT) in manufacturing market continues to evolve, driven by the increasing demand for automation, data analytics, and connectivity in the industrial sector. One key trend that is shaping the market is the focus on sustainability and environmental impact. Manufacturers are increasingly leveraging IoT technologies to optimize resource utilization, reduce waste, and improve energy efficiency in their operations. This shift towards sustainable manufacturing practices is not only driven by regulatory requirements but also by consumer preferences for eco-friendly products.

Another important development in the IoT in manufacturing market is the integration of digital twin technology. Digital twins enable manufacturers to create virtual replicas of physical assets, processes, and systems, allowing for real-time monitoring, simulation, and optimization. By leveraging digital twins, manufacturers can improve operational visibility, predict maintenance needs, and optimize production processes, leading to enhanced efficiency and cost savings. The adoption of digital twin technology is expected to drive further innovation and transformation in the manufacturing industry.

Furthermore, industry 4.0 initiatives are playing a significant role in shaping the future of manufacturing. Industry 4.0 encompasses technologies such as IoT, artificial intelligence, big data, and autonomous systems to create smart, interconnected factories. By embracing industry 4.0 principles, manufacturers can achieve greater flexibility, agility, and responsiveness in their operations. The integration of IoT solutions within the industry 4.0 framework is enabling manufacturers to automate decision-making processes, optimize production workflows, and enhance product quality.

Moreover, the continued emphasis on data security and privacy is driving manufacturers to invest in robust cybersecurity measures for their IoT deployments. As connected devices proliferate across manufacturing environments, ensuring the integrity and confidentiality of data becomes paramount. Manufacturers are implementing advanced encryption protocols, access controls, and monitoring systems to mitigate cybersecurity risks and safeguard their valuable intellectual property.

In conclusion, the IoT in manufacturing market is undergoing rapid advancement driven by technological innovations, industry trends, and evolving customer expectations. Manufacturers are embracing IoT solutions to optimize their operations, drive sustainability initiatives, and stay competitive in a dynamic market landscape. By leveraging the potential of IoT technologies, manufacturers can unlock new opportunities for growth, efficiency, and resilience in an increasingly digitalized world.The IoT in manufacturing market is experiencing a significant transformation as manufacturers increasingly adopt connected devices, automation technology, and data analytics to drive operational efficiency and productivity. One major trend shaping the market is the focus on sustainability, with manufacturers leveraging IoT solutions to optimize resource utilization, reduce waste, and enhance energy efficiency. This shift towards eco-friendly practices is driven by both regulatory requirements and consumer preferences for sustainable products, influencing the adoption of IoT technologies that support environmental initiatives within manufacturing operations.

Another critical development in the IoT in manufacturing market is the integration of digital twin technology. Digital twins enable manufacturers to create virtual replicas of physical assets and processes, facilitating real-time monitoring, simulation, and optimization. By leveraging digital twins, manufacturers can enhance operational visibility, predict maintenance needs, and optimize production processes for improved efficiency and cost savings. The adoption of digital twin technology is expected to drive further innovation and efficiency in the manufacturing sector, enabling manufacturers to make informed decisions and streamline operations.

Industry 4.0 initiatives are also playing a crucial role in reshaping the manufacturing landscape. Industry 4.0, characterized by the integration of IoT, artificial intelligence, big data, and autonomous systems, aims to create smart, interconnected factories. By embracing Industry 4.0 principles, manufacturers can achieve greater flexibility, agility, and responsiveness in their operations. The integration of IoT solutions within the Industry 4.0 framework enables manufacturers to automate decision-making processes, optimize production workflows, and improve product quality, leading to enhanced competitiveness and operational excellence in the digital era.

Additionally, ensuring data security and privacy remains a top priority for manufacturers deploying IoT solutions. With the proliferation of connected devices in manufacturing environments, safeguarding data integrity and confidentiality is paramount. Manufacturers are implementing robust cybersecurity measures, such as encryption protocols, access controls, and monitoring systems, to mitigate cybersecurity risks and protect intellectual property. Enhancing data security measures is crucial to maintaining trust and reliability in IoT deployments within the manufacturing sector.

In conclusion, the IoT in manufacturing market is evolving rapidly, driven by technological advancements, industry trends, and the growing emphasis on sustainability and efficiency. Manufacturers leveraging IoT solutions are poised to unlock new opportunities for growth, innovation, and competitive advantage in an increasingly digitalized manufacturing landscape. By embracing IoT technologies, manufacturers can optimize operations, drive sustainable practices, and meet the evolving demands of the market, positioning themselves for success in the era of smart manufacturing.

Understand how much market the company controls

https://www.databridgemarketresearch.com/reports/global-iot-in-manufacturing-market/companies

Alternative Market Research Questions for Internet of Things (IoT) in Manufacturing Sector Reports

- How is blockchain being integrated in supply chains?

- What B2B platforms are most popular in this Internet of Things (IoT) in Manufacturing Market?

- Which regions face regulatory restrictions?

- What portion of market growth is organic vs. inorganic?

- What predictive analytics tools are used?

- What is the average lead time for fulfillment?

- How is the Internet of Things (IoT) in Manufacturing Market affected by geopolitical tensions?

- What innovations are improving packaging?

- Which firms are leveraging SaaS tools in operations?

- How are customer retention strategies evolving?

- What are the pain points in after-sales service?

- What are the trends in mobile-first commerce?

- Which areas show declining Internet of Things (IoT) in Manufacturing Market interest?

- What AI tools are optimizing consumer targeting for Internet of Things (IoT) in Manufacturing Market?

Browse More Reports:

Global Veterinary Electrosurgery Market

Global VSaaS Market

Global Acanthamoeba Keratitis Treatment Market

Global Acrylic Resin Market

Global Active Wound Care Market

Global Acute Lymphocytic/Lymphoblastic Leukemia (ALL) Therapeutics Market

Global Aerosol Valves Market

Global Aerospace Direct Current (DC-DC) Converter Market

Global Afterburner Market

Global Agricultural Activator Adjuvants Market

Global Agricultural Chelates Market

Global Agriculture Robots Market

Global Air Quality Control Systems Market

Global Aircraft Brackets Market

Global Aldose Reductase Inhibitor Market

Global Algal Antioxidants Market

Global Allulose Market

Global Aluminum Trihydrate (ATH) Market

Global Alzheimer's Therapeutics Market

Global Ambulatory Electronic Health Records Market

Global Andalusite Market

Global Anesthesia Monitoring Devices Market

Global Anesthesia, Respiratory and Sleep Therapy Devices Market

Global Angiotensin Converting Enzyme (ACE) Inhibitors Market

Global Animal Protein Hydrolysate Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com