Stainless steel is more than just a construction material—it’s a symbol of innovation and reliability in the modern industrial world. The ability to produce high-precision alloys has revolutionized manufacturing processes across multiple industries. From surgical instruments to automotive parts, precision stainless steel ensures the perfect balance between strength, performance, and corrosion resistance.

With rapid industrialization and technology integration, the Precision Stainless Steel Market has entered an era of robust growth. The market’s expansion is being shaped by a combination of global sustainability initiatives, technological advancements, and rising end-user demands.

Enhanced machining accuracy and automated production systems have paved the way for customized, high-grade stainless steel components. This flexibility allows manufacturers to cater to niche industries while maintaining strict quality standards.

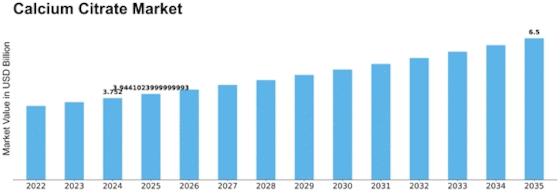

Recent Calcium Citrate Industry findings suggest that global industrial trends favor materials offering energy efficiency and low maintenance. Stainless steel’s recyclability and superior lifecycle performance make it an ideal choice for green construction and renewable energy systems.

The future of the precision stainless steel market lies in continuous innovation, material diversity, and environmentally sustainable production processes, ensuring that global industries can rely on durable solutions for decades to come.